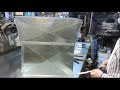

Thor Valve Grinder Trimming Valve Stem 8N Ford

Valve grinding has been taken to an art form with the modern race engine builders now grinding as many as 5 different precision angles to each valve face. The greater number of grind-angles does two things: 1). It creates a smoother flow pattern of the intake and exhaust gasses into and out of the combustion chamber. Its easier for a given volume of combustible gases to flow through a radius instead of a sharp angle. One valve grinding angle provides the latter, eating up horsepower (though miniscule) forcing the great volume through that perceived restriction. 2). The engine building guru's have found that there is a specific width of the 'sealing' (or seating) surface that is optimal for sealing the combustion products inside the cylinder as well as minimizing the transferrence of heat to the surface of the face and head of the valve. Everyone's heard of a 'burnt' valve..?? Yes, well carbon deposits have a greater tendency to attach to the wider single-angle ground exhaust valve surface than it does the more specific thinner sealing area of a multiple-angle ground valve. Think of it...the outer rim is thin, so heat is easily attracted to the thin edge causing the possibility of a burnt spot and eventually a failed valve. Now the blunt outer rim of a multiple-angle ground valve will not have the thinner edge to gain that excessive heat. Instead the whole valve runs a more consistent temperature with less chance of failure. Another thing...remember your old man telling you he's gotta 'Blow the cobwebs' outta this thing as he jams the pedal to the floor on the old '56 Ford that lives most of its life dogging around the farm in second gear....?? Well, the 'cobwebs' he's talking about is the carbon buildup in the cylinder head above the pistons due to 'dogging' around the farm. Yes, carbon is the byproduct of a not very efficient combustion process created by the way the engine is being run. These flakes of carbon easily become dislodged and in finding their way out to the tail pipe when the old man floored it leave a small percentage trapped on the valves sealing (or seating) surface. This will cause the black pitting (burning) so evident on almost all the exhaust valves in old engines. Excessive buildup causes the exhaust valve to no longer seat (or seal) correctly, causing a slight loss of compression in the cylinder. Slight loss of compression effects the way the atomized gas/air mixture ignites and flows across the top of the piston to do its work. In other words, the engine begins running less efficient, burning more fuel and providing less power to the drive wheels. Remember we are talking about only one valve in this case, but there are 8 of them in a V-8 and it is happening to all of them. Lets not go to the dual overhead cams and stuff like that....that's another episode. LOL.

Well, that's not what this video is about....its about the OTHER end of the valve. The stem. The combination of the length of the individual valves combined with the total height of the lifters (adjustable in this case) must be just perfectly long enough to be a few thousanths of an inch short of filling the gap between the top of the cam lobe and the seat (in the head of an over head valve engine or the seat in the block of a flat head engine) at the specific spot where the face of the newly ground valve rests. Hydraulic lifters and roller cam followers in new engines take a lot of the adjustments out of this process, but on a lot of these old tractors the lifters are adjustable. Occasionally you come up with a valve whose stem is just too darn long and will not fit in the given space. Time to trim the stem. Not too much but just enough to get it to adjust to the factory suggested settings of the particular engine you are working on by adjusting the adjustable lifters. This valve here was just too darn long, so there ensued the 'Trim the Stem' video of today.

Another time the stem may need to be trimmed is if the valve face was intentionally or accidentally ground too far down. That will make it sit lower in the seat....kinda like Cheech and Chong in their Chevy low rider... and by sitting lower, the stem now needs trimmed a few thousanths to get it within the required length. Now mind you, grinding the face of the valve just created another issue that is going to bite you in the rear. A super thin outer edge of either valve, intake OR exhaust will cause premature failure for sure. Especially if its the exhaust valve. Simply put the exhausting burnt fuel is hot and by comparison the incoming fuel/air mix is cool....its gonna burn quick.

Sorry you had to read so much, but if you did, don't shoot me if you don't agree with my above opinions.....LOL. That's ok....I ain't really a mechanic anyway.....AND this was all for your entertainment. Oh yeah I gave the reverse of the Camshaft-Crankshaft relationship. The Crankshaft turns two revolutions to one revolution of the Camshaft. LOL

Видео Thor Valve Grinder Trimming Valve Stem 8N Ford канала Tractorman44

Well, that's not what this video is about....its about the OTHER end of the valve. The stem. The combination of the length of the individual valves combined with the total height of the lifters (adjustable in this case) must be just perfectly long enough to be a few thousanths of an inch short of filling the gap between the top of the cam lobe and the seat (in the head of an over head valve engine or the seat in the block of a flat head engine) at the specific spot where the face of the newly ground valve rests. Hydraulic lifters and roller cam followers in new engines take a lot of the adjustments out of this process, but on a lot of these old tractors the lifters are adjustable. Occasionally you come up with a valve whose stem is just too darn long and will not fit in the given space. Time to trim the stem. Not too much but just enough to get it to adjust to the factory suggested settings of the particular engine you are working on by adjusting the adjustable lifters. This valve here was just too darn long, so there ensued the 'Trim the Stem' video of today.

Another time the stem may need to be trimmed is if the valve face was intentionally or accidentally ground too far down. That will make it sit lower in the seat....kinda like Cheech and Chong in their Chevy low rider... and by sitting lower, the stem now needs trimmed a few thousanths to get it within the required length. Now mind you, grinding the face of the valve just created another issue that is going to bite you in the rear. A super thin outer edge of either valve, intake OR exhaust will cause premature failure for sure. Especially if its the exhaust valve. Simply put the exhausting burnt fuel is hot and by comparison the incoming fuel/air mix is cool....its gonna burn quick.

Sorry you had to read so much, but if you did, don't shoot me if you don't agree with my above opinions.....LOL. That's ok....I ain't really a mechanic anyway.....AND this was all for your entertainment. Oh yeah I gave the reverse of the Camshaft-Crankshaft relationship. The Crankshaft turns two revolutions to one revolution of the Camshaft. LOL

Видео Thor Valve Grinder Trimming Valve Stem 8N Ford канала Tractorman44

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Pork Processing 2023 Plus Bacon Slicing

Pork Processing 2023 Plus Bacon Slicing Case 430 Loader Removal

Case 430 Loader Removal 8" to 7" Round Butt Joint Sheet Metal Hack Emergency Use Only

8" to 7" Round Butt Joint Sheet Metal Hack Emergency Use Only The Missus and The Frontier: First Red Oak Log of the Season Coming Soon #Shorts

The Missus and The Frontier: First Red Oak Log of the Season Coming Soon #Shorts E Z GO GOLF CART: How About Lets Troubleshoot It

E Z GO GOLF CART: How About Lets Troubleshoot It DIY Central A C Wall Bracket Repurposed Material Project

DIY Central A C Wall Bracket Repurposed Material Project Lets Talk Wood Pile Theory and Split a Little Wood By Hand; Suggest Reading Description-Its Fun

Lets Talk Wood Pile Theory and Split a Little Wood By Hand; Suggest Reading Description-Its Fun Frontier Sawmill Trailer Build Pt 1

Frontier Sawmill Trailer Build Pt 1 Lets Build Motorized Backdraft Dampers for Supply Air Plenum

Lets Build Motorized Backdraft Dampers for Supply Air Plenum DIY Home Made Scribe: Sheet Metal Hack

DIY Home Made Scribe: Sheet Metal Hack Lets Rip Some Strips and Talk Low VS High Voltage

Lets Rip Some Strips and Talk Low VS High Voltage PERSIMMON: Trash or Treasure You Decide- But Wait,Wasn't That Sassafras?

PERSIMMON: Trash or Treasure You Decide- But Wait,Wasn't That Sassafras? Sheet Metal-Fabrication- Furnace Change Out

Sheet Metal-Fabrication- Furnace Change Out Old Guy 1939, Older Tractor 1937 and Much Older Plow 1927

Old Guy 1939, Older Tractor 1937 and Much Older Plow 1927 Return Air Cabinet With Slight Corner Variation

Return Air Cabinet With Slight Corner Variation Case 580B Solenoid Change, 1973 Vintage

Case 580B Solenoid Change, 1973 Vintage Getting a Little Wood in Before the Ice and Snow

Getting a Little Wood in Before the Ice and Snow Old Tools and Stuff at The Much Older Brothers Shop

Old Tools and Stuff at The Much Older Brothers Shop Grooving Tool Handmade Lock for Round Pipe, Septic Tank Riser

Grooving Tool Handmade Lock for Round Pipe, Septic Tank Riser Callout to Old Sneelocks Workshop for Help Identifying a Tool

Callout to Old Sneelocks Workshop for Help Identifying a Tool BF Avery A Moved Under Roof

BF Avery A Moved Under Roof