Buzz Saw and Belsaw: A Needed Touch Up

A Dearborn buzz saw that was the subject of an 8 part series on conversion into a 3 point category 1 rig has been adapted for use as a stationary rig with remote power unit and driven by use of a flat belt. It's operation is exactly the same whether its powered by the right angle drive off the now dead 800 Ford or the PTO pully on the side of a different tractor....well....in theory anyway. The reality is the fact that it operates a bit better because of the increase in the diameter of the belt pully. The right angle drives pully is a bit smaller, but it is set up to deliver the arbor on the old saws at roughly 600 to 650 rpm through the wood. I haven't calculated it yet, but I'm guessing by the feel of it, the rpm is running 700 to 750 rpm. Is that bad...? Probably not too awful, but it is going to depend on the condition and type of bearings as to whether that increase is suggested or not.

If you have cheaper non-greaseable bearings, I would not recommend too much of an rpm increase. They have an expected life expectancy and chances are at their age, the increased rpm would signal an early death. If you have a higher quality grease able bearing set my suggestion is that it probably would not be too bad providing you keep good high quality grease in them. Some guys think grease is grease...but it is not. The suggestion is to pick the highest quality grease that doesn't lose its ability to stay in the bearing under heavy use, grease daily under heavy use and feel them occasionally to check for increased operating temperature.

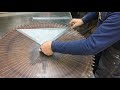

For years I hand filed the blades following the process learned from the old man from late in the '50's on. Fast forward to about 25 years ago when a buddy offered this old Belsaw model 10452 grinding tool as a trade for an old International B Cultivision with a bad engine. The 'even' trade resulted in the grinder and the whole compliment of the accessories that go with it....well...I'm missing the chain saw sharpening attachment, but hey, I can sharpen scissors. I digress....well it sat in the corner of the shed collecting dust for more than two decades until this exact saw was converted a couple years ago to a three point system. It was time to drag the grinder out and try to figure out how to put it to use. And boy am I glad I did. It has certainly lightened the burden of not only reshaping and sharpening, but just touching up the blades as well. So much quicker and much more accurate maintaining the geometry of the teeth all the way around the blade. It kinda aggravates me to have not pulled it out of the corner 20 years ago.....

So the video is 'old hat' to some that follow my videos but it may be that a few find it nice to see for possibly the first time. And of course there's the professional sharpening guys out there that really know their stuff that may be chuckling a bit to themselves at all the mistakes made.... But that's ok, if doctors can 'practice' medicine, a guy like me can 'practice' sharpening buzz saw blades don't you think...?

This is by no means a 'How to' video, and its total expressed intent is to provide the viewer a few minutes of entertainment watching an old guy with old tools working on an old saw rig. Oh yeah...I am continually searching for input for improving the quality of the result of the sharpening process. So If you've a suggestion, feel free to pass information on in the comments because its not only me you'll be helping...you may inadvertently be aiding those that read your comment as well.

Happy sharpening to all !!

Видео Buzz Saw and Belsaw: A Needed Touch Up канала Tractorman44

If you have cheaper non-greaseable bearings, I would not recommend too much of an rpm increase. They have an expected life expectancy and chances are at their age, the increased rpm would signal an early death. If you have a higher quality grease able bearing set my suggestion is that it probably would not be too bad providing you keep good high quality grease in them. Some guys think grease is grease...but it is not. The suggestion is to pick the highest quality grease that doesn't lose its ability to stay in the bearing under heavy use, grease daily under heavy use and feel them occasionally to check for increased operating temperature.

For years I hand filed the blades following the process learned from the old man from late in the '50's on. Fast forward to about 25 years ago when a buddy offered this old Belsaw model 10452 grinding tool as a trade for an old International B Cultivision with a bad engine. The 'even' trade resulted in the grinder and the whole compliment of the accessories that go with it....well...I'm missing the chain saw sharpening attachment, but hey, I can sharpen scissors. I digress....well it sat in the corner of the shed collecting dust for more than two decades until this exact saw was converted a couple years ago to a three point system. It was time to drag the grinder out and try to figure out how to put it to use. And boy am I glad I did. It has certainly lightened the burden of not only reshaping and sharpening, but just touching up the blades as well. So much quicker and much more accurate maintaining the geometry of the teeth all the way around the blade. It kinda aggravates me to have not pulled it out of the corner 20 years ago.....

So the video is 'old hat' to some that follow my videos but it may be that a few find it nice to see for possibly the first time. And of course there's the professional sharpening guys out there that really know their stuff that may be chuckling a bit to themselves at all the mistakes made.... But that's ok, if doctors can 'practice' medicine, a guy like me can 'practice' sharpening buzz saw blades don't you think...?

This is by no means a 'How to' video, and its total expressed intent is to provide the viewer a few minutes of entertainment watching an old guy with old tools working on an old saw rig. Oh yeah...I am continually searching for input for improving the quality of the result of the sharpening process. So If you've a suggestion, feel free to pass information on in the comments because its not only me you'll be helping...you may inadvertently be aiding those that read your comment as well.

Happy sharpening to all !!

Видео Buzz Saw and Belsaw: A Needed Touch Up канала Tractorman44

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Belsaw 10452 Buzz Saw Makeover Part 8

Belsaw 10452 Buzz Saw Makeover Part 8 Overloaded ?? Country Boys Guide to Loading Wood

Overloaded ?? Country Boys Guide to Loading Wood Stihl 660 and Big Oak Mashup

Stihl 660 and Big Oak Mashup Farmall H Removing Rusted Bolt With Candle Wax

Farmall H Removing Rusted Bolt With Candle Wax Sharpening a Swept Back Grind or Irish Grind on a Bowl Gouge - How To

Sharpening a Swept Back Grind or Irish Grind on a Bowl Gouge - How To 40's Allis Chalmers Speed Patrol and Kubota L3301 Grading Half Mile Drive

40's Allis Chalmers Speed Patrol and Kubota L3301 Grading Half Mile Drive Junkyard Run, Old Tractor, More Scrap Stuff and Trailer Built From Recycled Material

Junkyard Run, Old Tractor, More Scrap Stuff and Trailer Built From Recycled Material Old School Blow Torch Soldering Iron: Antique Tractor Radiator Repair

Old School Blow Torch Soldering Iron: Antique Tractor Radiator Repair Pole Saw Blade Maintenance - Prune Like a Pro

Pole Saw Blade Maintenance - Prune Like a Pro Farmall H Transmission Input Shaft Seal and Bearing Replacement

Farmall H Transmission Input Shaft Seal and Bearing Replacement Farmall H Transmission Cover Removal and Powerwashing Internals

Farmall H Transmission Cover Removal and Powerwashing Internals How to Sharpen a Chain Saw with the Harbor Freight Sharpener

How to Sharpen a Chain Saw with the Harbor Freight Sharpener How to Hammer a Circular Saw with Casey Creamer

How to Hammer a Circular Saw with Casey Creamer Splitter Wars 2020- Homebuilt PTO/ Hydraulic

Splitter Wars 2020- Homebuilt PTO/ Hydraulic Foley Belsaw 1055 Sharp All - Circular saw blade sharpening

Foley Belsaw 1055 Sharp All - Circular saw blade sharpening Buzz Saw Safety: Detailed Safety Discussion and Operation

Buzz Saw Safety: Detailed Safety Discussion and Operation Buzz Saw Blade, Preparation for Reshaping Teeth

Buzz Saw Blade, Preparation for Reshaping Teeth #36 Stretcher Roll

#36 Stretcher Roll Foley Belsaw 1055 Sharp All Fine Tuning and Use

Foley Belsaw 1055 Sharp All Fine Tuning and Use Pulling Pump On 285' Well

Pulling Pump On 285' Well