video of ceramic vacuum disc filter JXSC

Out side-drum vacuum filter is widely used in ore-processing, metallurgical industry, chemical plant, paper industry and etc, for dewatering floatation concentrates of non ferrous metals (such as copper, zinc, lead, nickel and etc,) and concentrates of non metal (such as sulphur, phosphorus, talcum, fluorite, coal and etc,) and can also be used for separating liquid and soild in suspensoids which are not easy to be setted down.

Structure: This kind of equipment is mainly composed of drum, trough, distribution head, blender, and transmission device.

Working Principle: During the operation of the filter, the slurry is fed into the trough. At this time, the slurry in the trough remains suspended as the result of the stirring of the blender. When the disc rotates, due to the vacuum in the vacuum filter, the solid materials are sucked from the slurry to the surface of the excircle of this drum submerged in the tank containing slurry. When the surface of the filter is exposed to vacuum, filter residual formation belt and dewatering belt are always retained. At this time, materials sticking to it begin to be sucked dry. When the drum continues to rotate, filter residual scraping belt appears. Here the vacuum inside the drum changes into compressed air. It blows down the filter residual and blow off through the filtration hole of filter cloth. To remove the filter residual on the filtering surface, a kind of special scraper shall be installed. Before slurry is reinfused to the surface of the drum, the surface of the filter is again affected by vacuum.

Видео video of ceramic vacuum disc filter JXSC канала JXSC Stan

Structure: This kind of equipment is mainly composed of drum, trough, distribution head, blender, and transmission device.

Working Principle: During the operation of the filter, the slurry is fed into the trough. At this time, the slurry in the trough remains suspended as the result of the stirring of the blender. When the disc rotates, due to the vacuum in the vacuum filter, the solid materials are sucked from the slurry to the surface of the excircle of this drum submerged in the tank containing slurry. When the surface of the filter is exposed to vacuum, filter residual formation belt and dewatering belt are always retained. At this time, materials sticking to it begin to be sucked dry. When the drum continues to rotate, filter residual scraping belt appears. Here the vacuum inside the drum changes into compressed air. It blows down the filter residual and blow off through the filtration hole of filter cloth. To remove the filter residual on the filtering surface, a kind of special scraper shall be installed. Before slurry is reinfused to the surface of the drum, the surface of the filter is again affected by vacuum.

Видео video of ceramic vacuum disc filter JXSC канала JXSC Stan

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

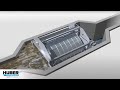

HUBER Disc Filter RoDisc® - animation

HUBER Disc Filter RoDisc® - animation Rotary vacuum belt filter HASLER Group - Filtres VERNAY

Rotary vacuum belt filter HASLER Group - Filtres VERNAY boyun new version animation of Ceramic Disc Filter Machinery

boyun new version animation of Ceramic Disc Filter Machinery ANDRITZ SEPARATION – Krauss-Maffei TSF vacuum drum filter

ANDRITZ SEPARATION – Krauss-Maffei TSF vacuum drum filter Ceramic Vacuum Disc Filter

Ceramic Vacuum Disc Filter CORES vacuum drum filter, an innovative solution for highly corrosive applications

CORES vacuum drum filter, an innovative solution for highly corrosive applications HUBER Drum Screen LIQUID - Animation

HUBER Drum Screen LIQUID - Animation Ceramic Filtering Machine

Ceramic Filtering Machine Criveller - 3 SQM Rotary Vacuum Drum Filter

Criveller - 3 SQM Rotary Vacuum Drum Filter Hydrotech Microscreens.mp4

Hydrotech Microscreens.mp4 Filtraflo TGV

Filtraflo TGV Disk Filter

Disk Filter Drum Screen Drumtec Wastewater video

Drum Screen Drumtec Wastewater video Filter Press Working | How Filter Press Work? | Filter Press Principle | Process of Filter Press

Filter Press Working | How Filter Press Work? | Filter Press Principle | Process of Filter Press Industrial Filtration - Removing Dirt and Sand From Process Cooling Systems - LAKOS

Industrial Filtration - Removing Dirt and Sand From Process Cooling Systems - LAKOS Tavlit semi automatic disc filter

Tavlit semi automatic disc filter Copper. Concentrating

Copper. Concentrating How RECTIFIED TILES are Made

How RECTIFIED TILES are Made ProfiDrum Combi Bio 30 at Absolute Koi

ProfiDrum Combi Bio 30 at Absolute Koi Cannon Artes - Self Backwashing Gravity Filters

Cannon Artes - Self Backwashing Gravity Filters