How to adjust the cans sealing machine electric sealer equip easy open tin kaleng penyegelan mesin

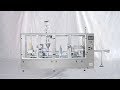

Model YX-41AA How to adjust the cans sealing machine electric sealer equipment for easy open tin kaleng penyegelan mesin designed and manufactured by our engineer team in cosmetic&food&pharma making and packaging machinery is widely used in the daily chemical industry like tin can sealing equipments and such like.We as a famous manufacturer moreover can design and produce the packaging machine according to the special requirements from customers.

This product Easy open cans/Metal jars/bottles sealing machine model YX-41AA is applicable to all kinds of tin cans, aluminum cans, plastic containers, paper, cans, and other kinds of round cans sealing, reliable quality, lightweight and easy to operate, the food and beverage industry and other essential ideal equipment.

Basic parameter of Model YX-41AA How to adjust the cans sealing machine electric sealer equipment for easy open tin kaleng penyegelan mesin:

Type YX-41AA

Voltage AC 220v /50 hz 110v / 60 hz

Power 0.55 kw

Can sealing height 30-320 mm

Can sealing diameter 50-200 mm

Operating air source 0.6 Mpa

Capacity 1200-2000 bottles/h

Size 600*660*1450 mm

Weight 140 kg

Features of cans/jars/bottles/metal caps sealing machine model YX-41AA

1. Sealed with sealing ring around, the roll seam sealing, simple structure, easy to adjust

2. Electrical components using Chint low-voltage electrical, reliable performance

3. Tank lift mechanical cam control, lifting stable and reliable

4. Work surface use 304 stainless steel

Trial Run Operation Procedures:

Step 1 : Check and Adjust to make sure the base plate and chuck are concentric

Methods:1. Place the easy open lid on the can body well and then put the can on the center of the base plate.

2. Pull the base plate up and check carefully if the easy open lid fully matches with the chuck.

3. If deviation exists, please adjust slightly by referencing to instruction videos.

Step 2: Adjust the base plate height

Method: 1.Pull the base plate to the highest point;

2.Place the empty can on the base plate and check to make sure the distance between the can lid and chuck to be at least 5mm.

3.If the height is not up to the requirement, please adjust the height lifting support by referencing to the instruction videos.

Step 3: Adjust the distance between 1st operation curling roll and the chuck.

Method:1. Pull the can seaming arm to make the seaming rolls start towards the chuck;

2.Visually inspect the gap distance between the seaming rolls and chuck to make sure it to be at least 1mm.

3.Adjust the reducer screw slightly if the distance is not correct by referencing to the instruction video.

Step 4: Adjust the distance between the 2nd operation forming roll and the chuck.

Method:1. Pull the can seaming arm to make its seaming rolls start towards the chuck Center.

2.Visually inspect the gap distance between seaming rolls and the chuck to make sure the distance at least 1mm;

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about various high quality machinery like Model YX-41AA How to adjust the cans sealing machine electric sealer equipment for easy open tin kaleng penyegelan mesin ,please email via jackdu999@yahoo.com or browse our website http://penglaichina.com.

Watch us on Youtube:http://youtube.com/user/penglaichina

Follow us on News Center:http://www.penglaichina.com/news/

Skype us by :turnanewleaf

Call us via:0086-15811882441

Whatsapp:0086-15811882441

Видео How to adjust the cans sealing machine electric sealer equip easy open tin kaleng penyegelan mesin канала Jack Du

This product Easy open cans/Metal jars/bottles sealing machine model YX-41AA is applicable to all kinds of tin cans, aluminum cans, plastic containers, paper, cans, and other kinds of round cans sealing, reliable quality, lightweight and easy to operate, the food and beverage industry and other essential ideal equipment.

Basic parameter of Model YX-41AA How to adjust the cans sealing machine electric sealer equipment for easy open tin kaleng penyegelan mesin:

Type YX-41AA

Voltage AC 220v /50 hz 110v / 60 hz

Power 0.55 kw

Can sealing height 30-320 mm

Can sealing diameter 50-200 mm

Operating air source 0.6 Mpa

Capacity 1200-2000 bottles/h

Size 600*660*1450 mm

Weight 140 kg

Features of cans/jars/bottles/metal caps sealing machine model YX-41AA

1. Sealed with sealing ring around, the roll seam sealing, simple structure, easy to adjust

2. Electrical components using Chint low-voltage electrical, reliable performance

3. Tank lift mechanical cam control, lifting stable and reliable

4. Work surface use 304 stainless steel

Trial Run Operation Procedures:

Step 1 : Check and Adjust to make sure the base plate and chuck are concentric

Methods:1. Place the easy open lid on the can body well and then put the can on the center of the base plate.

2. Pull the base plate up and check carefully if the easy open lid fully matches with the chuck.

3. If deviation exists, please adjust slightly by referencing to instruction videos.

Step 2: Adjust the base plate height

Method: 1.Pull the base plate to the highest point;

2.Place the empty can on the base plate and check to make sure the distance between the can lid and chuck to be at least 5mm.

3.If the height is not up to the requirement, please adjust the height lifting support by referencing to the instruction videos.

Step 3: Adjust the distance between 1st operation curling roll and the chuck.

Method:1. Pull the can seaming arm to make the seaming rolls start towards the chuck;

2.Visually inspect the gap distance between the seaming rolls and chuck to make sure it to be at least 1mm.

3.Adjust the reducer screw slightly if the distance is not correct by referencing to the instruction video.

Step 4: Adjust the distance between the 2nd operation forming roll and the chuck.

Method:1. Pull the can seaming arm to make its seaming rolls start towards the chuck Center.

2.Visually inspect the gap distance between seaming rolls and the chuck to make sure the distance at least 1mm;

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about various high quality machinery like Model YX-41AA How to adjust the cans sealing machine electric sealer equipment for easy open tin kaleng penyegelan mesin ,please email via jackdu999@yahoo.com or browse our website http://penglaichina.com.

Watch us on Youtube:http://youtube.com/user/penglaichina

Follow us on News Center:http://www.penglaichina.com/news/

Skype us by :turnanewleaf

Call us via:0086-15811882441

Whatsapp:0086-15811882441

Видео How to adjust the cans sealing machine electric sealer equip easy open tin kaleng penyegelan mesin канала Jack Du

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

DBL Seamer training

DBL Seamer training easy open cans sealing machine semi automatic metal lids sealer metálicos latas máquina de sellado

easy open cans sealing machine semi automatic metal lids sealer metálicos latas máquina de sellado How To Make A Rolled-Edge Aluminum Bottle Stove

How To Make A Rolled-Edge Aluminum Bottle Stove EVALUATING CAN DOUBLE SEAMS - EVALUANDO CIERRES DOBLES DE LATAS

EVALUATING CAN DOUBLE SEAMS - EVALUANDO CIERRES DOBLES DE LATAS fully automatic blister boxing cartoning packs tapes sealing line with hot melt glue device

fully automatic blister boxing cartoning packs tapes sealing line with hot melt glue device Power Press and Fly Press Sheet Metal Work

Power Press and Fly Press Sheet Metal Work Straight Line Wrapping Machine Pharmaceutical Boxes Bundle Strapping Equipment صناديق آلة الربط

Straight Line Wrapping Machine Pharmaceutical Boxes Bundle Strapping Equipment صناديق آلة الربط S-1 Manual Round Can Seamer, Jk Somme

S-1 Manual Round Can Seamer, Jk Somme Square Can making Production Line

Square Can making Production Line Nylon bands sealing strapping machine instruction demo cartons strapper flejadora de bandas

Nylon bands sealing strapping machine instruction demo cartons strapper flejadora de bandas Food Storage: Great Northern Beans, in # 10 Cans

Food Storage: Great Northern Beans, in # 10 Cans Integrated Multihead weighing noodles bagging packaging equipment with concentration delivery system

Integrated Multihead weighing noodles bagging packaging equipment with concentration delivery system Oktober Can Seamers: Seam Inspection

Oktober Can Seamers: Seam Inspection Square tin making process of Ashok Machine Tools

Square tin making process of Ashok Machine Tools Making A Double Seam

Making A Double Seam CAN SEAMER 72.8mm DEMO VIDEO

CAN SEAMER 72.8mm DEMO VIDEO Rectangular Can Body Making Line

Rectangular Can Body Making Line semi auto electric sealing machine for aluminum metal can semi-automatique peut sceller la machine

semi auto electric sealing machine for aluminum metal can semi-automatique peut sceller la machine Automatic A4 paper office products packing machine Máquina de embalaje de papel de oficina

Automatic A4 paper office products packing machine Máquina de embalaje de papel de oficina Fully automatic cups Bio Herb powder filling sealing with weight check sterilizer system حشو مسحوق

Fully automatic cups Bio Herb powder filling sealing with weight check sterilizer system حشو مسحوق