How Primary Clarifiers Work

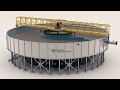

This 3D animated video shows how a circular primary clarifier works. We look at all of the main components of the clarifier, how it works and the factors that influence its performance.

Like this video? Then check out our other videos!

🚢 Marine Diesel Two Stroke Engine - How it Works! - https://youtu.be/IM8rxp8qB8k

🚢 Ship Parts and Terminology Explained! - https://youtu.be/Xm-F2rPU_NU

⚙️How Deaerators Work! - https://youtu.be/M_jOsTWVIH8

⚙️How Shell and Tube Heat Exchangers Work! - https://youtu.be/OyQ3SaU4KKU

⚙️How Power Grids Work! - https://youtu.be/fUWRyhsutL8

⚙️How Watertube Boilers Work! - https://youtu.be/fUWRyhsutL8

⚙️How Dams Work (Hydro Dams)! - https://youtu.be/ztM6tL6LtFs

💡Control Valve Types (Gate Valve, Globe Valve etc.)! - https://youtu.be/OyQ3SaU4KKU

💡Transformer Parts and Functions! - https://youtu.be/3osmO4FQ2Yg

💡Plate Heat Exchangers Explained! - https://youtu.be/7TTF4aU3Pcs

📚Want to learn more about engineering?

Then join saVRee to access over 45 hours of engineering video courses! New courses every month!

https://courses.savree.com/

Hope to see you on a course soon! 👋

🏫Want to use the 3D model in this video to present, instruct, or teach? Simply join saVRee! We have over 400 engineering models that will make your life a lot easier!

https://savree.com/

📱Check out our socials!

https://linktr.ee/savree

📖You can learn more about engineering in our technical encyclopedia: https://savree.com/en/encyclopedia

▶️Introduction

Primary clarifiers are used to complete the process of sedimentation. Sedimentation is the process of separating suspended solids from a liquid. Separation without mechanical means can be completed within a sedimentation basin or settling tank, separation using mechanical means is completed using a clarifier.

Clarifiers are used in many water treatment facilities, as well as in the mining, paper and pulp, and sanitation industries. Clarifiers can be of the rectangular, sloped or circular design.

The purpose of the clarifier is to reduce the velocity of the influent in order to allow the suspended solids to separate from the liquid. Heavy solids are referred to as settleable solids and these accumulate on the bottom of the clarifier to form sludge. Lighter solids are referred to as floatable solids and these accumulate on the liquid surface to form scum.

Clarifiers have found widespread application because they are very effective and offer a good return on investment compared to other alternatives. A typical primary clarifier will separate between 90-95% of settleable solids from the liquid and 40-60% of suspended solids.

How It Works

Influent enters through the central pipe and is discharged to the centre of the clarifier. The influent velocity is reduced and settling occurs due to gravity. Heavier solids form sludge and are removed using rakes/ploughs. Lighter solids float on the top of the liquid and are removed by a scum skimmer. The cleaned liquid passes through a weir and into the effluent launder. The effluent is then extracted for direct discharge or further treatment.

Sources:

By 19ceic3004 - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=29027554

eCompendium of sanitation systems and technologies: http://ecompendium.sswm.info/sanitation-technologies

Eawag: Swiss Federal Institute of Aquatic Science and Technology

Technical drawings: designport, Paolo Monaco, Zurich

See http://ecompendium.sswm.info/copyright

By User:Dantadd - Own work, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=1909908

#saVRee #PowerEngineering #IndustrialEngineering

Видео How Primary Clarifiers Work канала saVRee

Like this video? Then check out our other videos!

🚢 Marine Diesel Two Stroke Engine - How it Works! - https://youtu.be/IM8rxp8qB8k

🚢 Ship Parts and Terminology Explained! - https://youtu.be/Xm-F2rPU_NU

⚙️How Deaerators Work! - https://youtu.be/M_jOsTWVIH8

⚙️How Shell and Tube Heat Exchangers Work! - https://youtu.be/OyQ3SaU4KKU

⚙️How Power Grids Work! - https://youtu.be/fUWRyhsutL8

⚙️How Watertube Boilers Work! - https://youtu.be/fUWRyhsutL8

⚙️How Dams Work (Hydro Dams)! - https://youtu.be/ztM6tL6LtFs

💡Control Valve Types (Gate Valve, Globe Valve etc.)! - https://youtu.be/OyQ3SaU4KKU

💡Transformer Parts and Functions! - https://youtu.be/3osmO4FQ2Yg

💡Plate Heat Exchangers Explained! - https://youtu.be/7TTF4aU3Pcs

📚Want to learn more about engineering?

Then join saVRee to access over 45 hours of engineering video courses! New courses every month!

https://courses.savree.com/

Hope to see you on a course soon! 👋

🏫Want to use the 3D model in this video to present, instruct, or teach? Simply join saVRee! We have over 400 engineering models that will make your life a lot easier!

https://savree.com/

📱Check out our socials!

https://linktr.ee/savree

📖You can learn more about engineering in our technical encyclopedia: https://savree.com/en/encyclopedia

▶️Introduction

Primary clarifiers are used to complete the process of sedimentation. Sedimentation is the process of separating suspended solids from a liquid. Separation without mechanical means can be completed within a sedimentation basin or settling tank, separation using mechanical means is completed using a clarifier.

Clarifiers are used in many water treatment facilities, as well as in the mining, paper and pulp, and sanitation industries. Clarifiers can be of the rectangular, sloped or circular design.

The purpose of the clarifier is to reduce the velocity of the influent in order to allow the suspended solids to separate from the liquid. Heavy solids are referred to as settleable solids and these accumulate on the bottom of the clarifier to form sludge. Lighter solids are referred to as floatable solids and these accumulate on the liquid surface to form scum.

Clarifiers have found widespread application because they are very effective and offer a good return on investment compared to other alternatives. A typical primary clarifier will separate between 90-95% of settleable solids from the liquid and 40-60% of suspended solids.

How It Works

Influent enters through the central pipe and is discharged to the centre of the clarifier. The influent velocity is reduced and settling occurs due to gravity. Heavier solids form sludge and are removed using rakes/ploughs. Lighter solids float on the top of the liquid and are removed by a scum skimmer. The cleaned liquid passes through a weir and into the effluent launder. The effluent is then extracted for direct discharge or further treatment.

Sources:

By 19ceic3004 - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=29027554

eCompendium of sanitation systems and technologies: http://ecompendium.sswm.info/sanitation-technologies

Eawag: Swiss Federal Institute of Aquatic Science and Technology

Technical drawings: designport, Paolo Monaco, Zurich

See http://ecompendium.sswm.info/copyright

By User:Dantadd - Own work, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=1909908

#saVRee #PowerEngineering #IndustrialEngineering

Видео How Primary Clarifiers Work канала saVRee

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Wastewater Treatment Plant Virtual Tour

Wastewater Treatment Plant Virtual Tour CVE 351 - Class 14 (Settling and Clarifiers) 13 Oct 2015

CVE 351 - Class 14 (Settling and Clarifiers) 13 Oct 2015 Krofta Supracell DAF Liquid Solid Separation

Krofta Supracell DAF Liquid Solid Separation Marine Diesel Two Stroke Engine - How it Works!

Marine Diesel Two Stroke Engine - How it Works! How Flue Gas Desulfurization (FGD) Works

How Flue Gas Desulfurization (FGD) Works How Ball Mills Work (Engineering and Mining)

How Ball Mills Work (Engineering and Mining) CIRCULAR SEDIMENTATION TANK-Animation (Fluid Simulation included)

CIRCULAR SEDIMENTATION TANK-Animation (Fluid Simulation included) Clarifier basics - How do clarifiers work I Clarifier design

Clarifier basics - How do clarifiers work I Clarifier design Control Valve Types (Gate Valve, Globe Valve, Ball Valve etc.)!

Control Valve Types (Gate Valve, Globe Valve, Ball Valve etc.)!

How do ball and roller bearings work? Types and durability calculation. DIN ISO 281

How do ball and roller bearings work? Types and durability calculation. DIN ISO 281 DIEMME FILTRATION HIGH RATE THICKENER

DIEMME FILTRATION HIGH RATE THICKENER Aerobic Digestion: Learning the chemistry behind the Aerobic Digestion process

Aerobic Digestion: Learning the chemistry behind the Aerobic Digestion process Dissolved Air Flotation (DAF) System - Ideal DAF™

Dissolved Air Flotation (DAF) System - Ideal DAF™ How Deaerators Work (Engineering)

How Deaerators Work (Engineering) The Surprising Efficiency of Canal Locks

The Surprising Efficiency of Canal Locks Bed level, Density and Solids: Measurement applications in a Thickener tank

Bed level, Density and Solids: Measurement applications in a Thickener tank All Things Water Course I, Activated Sludge

All Things Water Course I, Activated Sludge Flocculation and coagulation - floc forming and particle settling

Flocculation and coagulation - floc forming and particle settling Rimflo Circular Clarifier Video

Rimflo Circular Clarifier Video