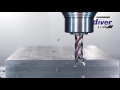

Using a Button Cutter to High Feed Ramp a Mold Core, then Plunge Finishing for Shortest Cycle Time

Mold core roughing can be very effectively done using high-feed ramping, even with a button cutter! Dapra's DTB-series double-sided button cutters are robust, 12-index tools that allow aggressive metal removal, without the dependence on exact depth of cut like high feed cutters require. In this video, Dapra shows a real-world example of how to use the high-feed ramping technique with this style cutter.

Mold core finishing can be done with various different cutter styles. One of the most efficient ways is to use a smaller-radius bull-nose style tool, but in a plunge finishing approach vs traditional profiling. Ball nose and barrel-style cutters can take a large step down, but also create more tool pressure due the increase in surface-area contact, potentially costing size and time due to the need for subsequent additional finish passes. Using a bull-nose style tool minimizes tool pressure, and using plunge finishing causes the CAM software to calculate stepover by cutter diameter, minimizing cycle time.

For more information on how to use either of these techniques in your shop, contact Dapra at 800-243-3344, or info@dapra.com.

#YourJobOurJob

Видео Using a Button Cutter to High Feed Ramp a Mold Core, then Plunge Finishing for Shortest Cycle Time канала DAPRA

Mold core finishing can be done with various different cutter styles. One of the most efficient ways is to use a smaller-radius bull-nose style tool, but in a plunge finishing approach vs traditional profiling. Ball nose and barrel-style cutters can take a large step down, but also create more tool pressure due the increase in surface-area contact, potentially costing size and time due to the need for subsequent additional finish passes. Using a bull-nose style tool minimizes tool pressure, and using plunge finishing causes the CAM software to calculate stepover by cutter diameter, minimizing cycle time.

For more information on how to use either of these techniques in your shop, contact Dapra at 800-243-3344, or info@dapra.com.

#YourJobOurJob

Видео Using a Button Cutter to High Feed Ramp a Mold Core, then Plunge Finishing for Shortest Cycle Time канала DAPRA

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Plunge Milling - Great for Roughing & Slotting! WW205

Plunge Milling - Great for Roughing & Slotting! WW205 Walter Tools M4000–one insert for Face-,shoulder- chamfer milling

Walter Tools M4000–one insert for Face-,shoulder- chamfer milling 10 Amazing Metal Work Processes You Must See

10 Amazing Metal Work Processes You Must See Woodturning - A Waterfall Vase !!

Woodturning - A Waterfall Vase !! Seco Tools :High Feed & Dyk Fræsning - DMU 75 -Harun Göbekoglu - Danmark

Seco Tools :High Feed & Dyk Fræsning - DMU 75 -Harun Göbekoglu - Danmark Using a TAP as Thread Boring Tool

Using a TAP as Thread Boring Tool How to cut a thread on a manual lathe (Intermediate method ideal for home workshop & hobby engineer)

How to cut a thread on a manual lathe (Intermediate method ideal for home workshop & hobby engineer) MillQuadFeed - New generation of high feed milling cutter with versatility and long life

MillQuadFeed - New generation of high feed milling cutter with versatility and long life Roughing Comparison: High-Feed Ramping vs. High-Efficiency Milling – Which is More Efficient?

Roughing Comparison: High-Feed Ramping vs. High-Efficiency Milling – Which is More Efficient? Next Generation Tools that Everyone Must Have

Next Generation Tools that Everyone Must Have Master the G71 Roughing Cycle! - Haas Automation Tip of the Day

Master the G71 Roughing Cycle! - Haas Automation Tip of the Day EMUGE-FRANKEN MOTORBLOCK

EMUGE-FRANKEN MOTORBLOCK Tool Holder Essentials - Every Machinist Needs to Watch This - Haas Automation Tip of the Day

Tool Holder Essentials - Every Machinist Needs to Watch This - Haas Automation Tip of the Day Letter Punch Guide : Straight and Tidy Every Time!

Letter Punch Guide : Straight and Tidy Every Time! How to Face & Engrave 304 Stainless Steel | WW251

How to Face & Engrave 304 Stainless Steel | WW251 Guhring Diver End Mill

Guhring Diver End Mill Pramet SBN10 high feed milling cutters with BNGX inserts

Pramet SBN10 high feed milling cutters with BNGX inserts Cool idea! Most useful tool for every home!

Cool idea! Most useful tool for every home! High Feed 6 Demonstration | Seco Tools

High Feed 6 Demonstration | Seco Tools Mold Insert Chase Pocket Roughing & Finishing – Live Cutting Tool Footage (Condensed Version)

Mold Insert Chase Pocket Roughing & Finishing – Live Cutting Tool Footage (Condensed Version)