Amazing New drilling technology ,Flow Drilling

Amazing New drilling technology ,Flow Drilling

Examples of new drilling technologies

There are more than 20 research efforts solving innovative drilling technology such as: laser, spallation, plasma, electron beam, pallets, enhanced rotary, electric spark and discharge, electric arc, water jet erosion, ultrasonic, chemical, induction, nuclear, forced flame explosive, turbine, high frequency, microwave, heating/cooling stress, electric current and several other. The most promising solutions are mentioned below:

1. Hydrothermal spallation – Thermal spallation drilling uses a large, downhole burner, much like a jet engine, to apply a high heat flux to the rock face. This drilling technology is based on thermal processes of rock spallation and fusion.

2. Chemical plasma – is based on crushing by high-speed combustion, but nitric acid as oxidizing agent instead of oxygen.

3. Erosion - most patents refer to water jet rock cutting. Different modification variants are described, e.g. utilization of cavitation, turbulent processes, combination with mechanical processes, etc.

4. Laser - during the recent decade intense research has been made into utilization of high energy laser beams for rock disintegration. Primarily conversion of military equipment is concerned. Laser energy is used for the process of thermal spallation, melting, or evaporation of rock.

5. Electric discharge - The methods utilizing electric discharge are based on long-term experience gained in other application areas.

6. Electrical plasma - is based on crushing by irradiation of plasma with high temperature up to 20 000°C

7. Direct transfer of heat - This technology is based on electrically melting rock at 1400°C; lava gravel will float to top; bore hole walls are of glass of surrounding rock. Cost decreases with depth, with no limit on depth of bore hole. Bore diameters from 1m to 10m. Recovery of energy used to melt rock.

---

Friction drilling is a method of making holes in metal in which the material is pushed out of the way with the aid of heat from friction. The process is also called thermal drilling, flow drilling, form drilling, or friction stir drilling.

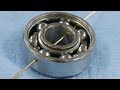

Friction drilling is commonly used on bicycle frames, heat exchangers, and to create holes for mounting bearings.

Advantages

Very quick process (2 to 6 seconds)

The process reshapes all material so that no material is lost. The excess material forms a sleeve that is about 3 times longer than the original thickness of the target material, which makes it possible to make very strong bolt joints in thin material.

It is a clean process because no litter (particles) is produced.

No access needed to back of workpiece, as with rivet nuts.

Works in almost all kinds of metal.

#HDVideoRidha

THANKS FOR WATCHING! SUBSCRIBE, LIKE, SHARE FOR MORE VIDEOS!❤❤❤👍

God bless you

Website: https://autovehiclex.blogspot.com/

Facebook: https://www.facebook.com/youtubexridha/

Twitter: https://twitter.com/1ridha

Google+: https://plus.google.com/u/0/116462490999076441831

tumblr: http://ridha.tumblr.com/

Видео Amazing New drilling technology ,Flow Drilling канала HDVideoRidha

Examples of new drilling technologies

There are more than 20 research efforts solving innovative drilling technology such as: laser, spallation, plasma, electron beam, pallets, enhanced rotary, electric spark and discharge, electric arc, water jet erosion, ultrasonic, chemical, induction, nuclear, forced flame explosive, turbine, high frequency, microwave, heating/cooling stress, electric current and several other. The most promising solutions are mentioned below:

1. Hydrothermal spallation – Thermal spallation drilling uses a large, downhole burner, much like a jet engine, to apply a high heat flux to the rock face. This drilling technology is based on thermal processes of rock spallation and fusion.

2. Chemical plasma – is based on crushing by high-speed combustion, but nitric acid as oxidizing agent instead of oxygen.

3. Erosion - most patents refer to water jet rock cutting. Different modification variants are described, e.g. utilization of cavitation, turbulent processes, combination with mechanical processes, etc.

4. Laser - during the recent decade intense research has been made into utilization of high energy laser beams for rock disintegration. Primarily conversion of military equipment is concerned. Laser energy is used for the process of thermal spallation, melting, or evaporation of rock.

5. Electric discharge - The methods utilizing electric discharge are based on long-term experience gained in other application areas.

6. Electrical plasma - is based on crushing by irradiation of plasma with high temperature up to 20 000°C

7. Direct transfer of heat - This technology is based on electrically melting rock at 1400°C; lava gravel will float to top; bore hole walls are of glass of surrounding rock. Cost decreases with depth, with no limit on depth of bore hole. Bore diameters from 1m to 10m. Recovery of energy used to melt rock.

---

Friction drilling is a method of making holes in metal in which the material is pushed out of the way with the aid of heat from friction. The process is also called thermal drilling, flow drilling, form drilling, or friction stir drilling.

Friction drilling is commonly used on bicycle frames, heat exchangers, and to create holes for mounting bearings.

Advantages

Very quick process (2 to 6 seconds)

The process reshapes all material so that no material is lost. The excess material forms a sleeve that is about 3 times longer than the original thickness of the target material, which makes it possible to make very strong bolt joints in thin material.

It is a clean process because no litter (particles) is produced.

No access needed to back of workpiece, as with rivet nuts.

Works in almost all kinds of metal.

#HDVideoRidha

THANKS FOR WATCHING! SUBSCRIBE, LIKE, SHARE FOR MORE VIDEOS!❤❤❤👍

God bless you

Website: https://autovehiclex.blogspot.com/

Facebook: https://www.facebook.com/youtubexridha/

Twitter: https://twitter.com/1ridha

Google+: https://plus.google.com/u/0/116462490999076441831

tumblr: http://ridha.tumblr.com/

Видео Amazing New drilling technology ,Flow Drilling канала HDVideoRidha

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Flowdrill Instruction - Starter set - Thermal friction drilling

Flowdrill Instruction - Starter set - Thermal friction drilling Welding Workers Who Are Professional and Experts Of High Level ▶3

Welding Workers Who Are Professional and Experts Of High Level ▶3 Drill through anything (conductive) with Electrical Discharge Machining

Drill through anything (conductive) with Electrical Discharge Machining Dangerous Biggest Heavy Duty Lathe Machining Working, Fastest CNC Lathe Machine Modern Technology

Dangerous Biggest Heavy Duty Lathe Machining Working, Fastest CNC Lathe Machine Modern Technology How Much Money Should I Charge for My Welds?

How Much Money Should I Charge for My Welds? THIS IS AMAZING, THE WATER CUTS THE STONE! YOU MUST SEE IT!

THIS IS AMAZING, THE WATER CUTS THE STONE! YOU MUST SEE IT! Drilling,Tapping,Slotting and Milling By Industrial Cnc Machines - High Resistance Cnc Tools

Drilling,Tapping,Slotting and Milling By Industrial Cnc Machines - High Resistance Cnc Tools Fastest CNC Lathe Machine Working, Modern Technology CNC Milling Machine Metal

Fastest CNC Lathe Machine Working, Modern Technology CNC Milling Machine Metal flow drill friction drill drilling at home

flow drill friction drill drilling at home Présentation du Fluoperçage et Fluotaraudage- Outillage // ⓇⒷ

Présentation du Fluoperçage et Fluotaraudage- Outillage // ⓇⒷ Friction welding

Friction welding 11 DRILLING TIPS AND TRICKS (And Mistakes To Avoid!)

11 DRILLING TIPS AND TRICKS (And Mistakes To Avoid!) Everything you need to know about drilling and tapping holes | DIY

Everything you need to know about drilling and tapping holes | DIY Fast Extreme Water Jet Cutter Machine Working, Modern Technology Waterjet Cutting Compilation

Fast Extreme Water Jet Cutter Machine Working, Modern Technology Waterjet Cutting Compilation Does Cutting Oil for Drilling Metal Help? Let's find out!

Does Cutting Oil for Drilling Metal Help? Let's find out! Welding and Drilling Non-Ferrous with Tungsten

Welding and Drilling Non-Ferrous with Tungsten Most Satisfying Factory Machines and Ingenious Tools ▶2

Most Satisfying Factory Machines and Ingenious Tools ▶2 How to Flowdrill on CNC using FlexCNC Biggest Thermal Drill EVER - Live Demo

How to Flowdrill on CNC using FlexCNC Biggest Thermal Drill EVER - Live Demo So I Bought A Cold Welder

So I Bought A Cold Welder Friction welding

Friction welding