circular pocket milling program || without use sub program || only one block || vmc programming

circular pocket milling program || without use sub program || only one block || vmc programming

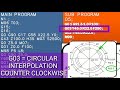

G12 Circular Pocket Milling CW / G13 Circular Pocket Milling CCW

These G-codes mill circular shapes. They are different only in that G12 uses a clockwise

direction and G13 uses a counterclockwise direction. Both G-codes use the default XY

circular plane (G17) and imply the use of G42 (cutter compensation) for G12 and G41 for

G13. G12 and G13 are non-modal.

D - Tool radius or diameter selection**

F - Feedrate

I - Radius of first circle (or finish if no K). I value must be greater than Tool Radius, but less

than K value.

K - Radius of finished circle (if specified)

L - Loop count for repeating deeper cuts

Q - Radius increment, or stepover (must be used with K)

Z - Depth of cut or increment

indicates optional

To get the programmed circle diameter, the control uses the selected D code tool size.

To program tool centerline select D0.

NOTE: Specify D00 if you do not want to use cutter compensation. If you do

not specify a D value in the G12/G13 block, the control uses the last

commanded D value, even if it was previously canceled with a G40.

Rapid-position the tool to the center of the circle. To remove all the material inside the

circle, use I and Q values less than the tool diameter and a K value equal to the circle

radius. To cut a circle radius only, use an I value set to the radius and no K or Q value.

Example G13 multiple-pass using I, K, Q, L, and G91:

This program uses G91 and an L count of 4, so this cycle will execute a total of four times.

The Z depth increment is 0.500. This is multiplied by the L count, making the total depth of

this hole 2.000.

The G91 and L count can also be used in a G13 I only line.

O60131 (G13 G91 CCW EXAMPLE) ;

(G54 X0 Y0 is center of 1st pocket) ;

(Z0 is on top of the part) ;

(T1 is a 0.5 in. dia endmill) ;

(BEGIN PREPARATION BLOCKS) ;

T1 M06 (Select tool 1) ;

G00 G90 G40 G49 G54 (Safe startup) ;

G00 G54 X0 Y0 (Rapid to 1st position) ;

S1000 M03 (Spindle on CW) ;

G43 H01 Z0.1 (Activate tool offset 1) ;

M08 (Coolant on) ;

(BEGIN CUTTING BLOCKS) ;

G13 G91 Z-.5 I.400 K2.0 Q.400 L4 D01 F20. ;

(Rough & finish CCW) ;

(BEGIN COMPLETION BLOCKS) ;

G00 G90 Z0.1 M09 (Rapid retract, coolant off) ;

G53 G49 Z0 M05 (Z home, spindle off) ;

G53 Y0 (Y home) ;

M30 (End program)

#CircularPocketMilling

#NotUseSubProgram

Thanks for Watching

Like 👍👍

Share

Subscribe Our Channel

Видео circular pocket milling program || without use sub program || only one block || vmc programming канала Amazing Gyan Tech 3M

G12 Circular Pocket Milling CW / G13 Circular Pocket Milling CCW

These G-codes mill circular shapes. They are different only in that G12 uses a clockwise

direction and G13 uses a counterclockwise direction. Both G-codes use the default XY

circular plane (G17) and imply the use of G42 (cutter compensation) for G12 and G41 for

G13. G12 and G13 are non-modal.

D - Tool radius or diameter selection**

F - Feedrate

I - Radius of first circle (or finish if no K). I value must be greater than Tool Radius, but less

than K value.

K - Radius of finished circle (if specified)

L - Loop count for repeating deeper cuts

Q - Radius increment, or stepover (must be used with K)

Z - Depth of cut or increment

indicates optional

To get the programmed circle diameter, the control uses the selected D code tool size.

To program tool centerline select D0.

NOTE: Specify D00 if you do not want to use cutter compensation. If you do

not specify a D value in the G12/G13 block, the control uses the last

commanded D value, even if it was previously canceled with a G40.

Rapid-position the tool to the center of the circle. To remove all the material inside the

circle, use I and Q values less than the tool diameter and a K value equal to the circle

radius. To cut a circle radius only, use an I value set to the radius and no K or Q value.

Example G13 multiple-pass using I, K, Q, L, and G91:

This program uses G91 and an L count of 4, so this cycle will execute a total of four times.

The Z depth increment is 0.500. This is multiplied by the L count, making the total depth of

this hole 2.000.

The G91 and L count can also be used in a G13 I only line.

O60131 (G13 G91 CCW EXAMPLE) ;

(G54 X0 Y0 is center of 1st pocket) ;

(Z0 is on top of the part) ;

(T1 is a 0.5 in. dia endmill) ;

(BEGIN PREPARATION BLOCKS) ;

T1 M06 (Select tool 1) ;

G00 G90 G40 G49 G54 (Safe startup) ;

G00 G54 X0 Y0 (Rapid to 1st position) ;

S1000 M03 (Spindle on CW) ;

G43 H01 Z0.1 (Activate tool offset 1) ;

M08 (Coolant on) ;

(BEGIN CUTTING BLOCKS) ;

G13 G91 Z-.5 I.400 K2.0 Q.400 L4 D01 F20. ;

(Rough & finish CCW) ;

(BEGIN COMPLETION BLOCKS) ;

G00 G90 Z0.1 M09 (Rapid retract, coolant off) ;

G53 G49 Z0 M05 (Z home, spindle off) ;

G53 Y0 (Y home) ;

M30 (End program)

#CircularPocketMilling

#NotUseSubProgram

Thanks for Watching

Like 👍👍

Share

Subscribe Our Channel

Видео circular pocket milling program || without use sub program || only one block || vmc programming канала Amazing Gyan Tech 3M

Показать

Комментарии отсутствуют

Информация о видео

Другие видео канала

Lecture 5 - G12 Circular Pocket Milling Cycle (CW) (for HASS controller)

Lecture 5 - G12 Circular Pocket Milling Cycle (CW) (for HASS controller) circular pocket milling program || how to Write a 2D pocket program in vmc machine

circular pocket milling program || how to Write a 2D pocket program in vmc machine HOW TO USE G16 FOR CIRCULAR SLOT MILLING PROGRAM in hindi

HOW TO USE G16 FOR CIRCULAR SLOT MILLING PROGRAM in hindi VMC WORK OFFSET | CORNER WORK OFFSET ON VMC MACHINE

VMC WORK OFFSET | CORNER WORK OFFSET ON VMC MACHINE VMC Tool runout checking

VMC Tool runout checking fixture hole dialing || datum setting || round work offset || fixture Setting

fixture hole dialing || datum setting || round work offset || fixture Setting Cnc Circular Interpolation I & J - Cnc Circular Interpolation Example - Cnc Interpolation Program

Cnc Circular Interpolation I & J - Cnc Circular Interpolation Example - Cnc Interpolation Program VMC 2D SLOT PROGRAMING | SLOT PROGRAM KESE KARE | HOW TO CREATE SLOT PROGRAM IN VMC MACHINE |

VMC 2D SLOT PROGRAMING | SLOT PROGRAM KESE KARE | HOW TO CREATE SLOT PROGRAM IN VMC MACHINE | VMC 3 axis machining

VMC 3 axis machining How to Write a Ramp Milling Program || Helix Interpolation || Spiral Milling || vmc 2D Program

How to Write a Ramp Milling Program || Helix Interpolation || Spiral Milling || vmc 2D Program CIRCULAR POCKET MILLING || VMC PROGRAMMING || M98 AND M99 CNC CODE

CIRCULAR POCKET MILLING || VMC PROGRAMMING || M98 AND M99 CNC CODE BFW Xtron 544 #VMC #Micromatic vs. #Bfw #AMS #Cnc #machine #automobile

BFW Xtron 544 #VMC #Micromatic vs. #Bfw #AMS #Cnc #machine #automobile Vmc programming || pcd programming || how to calculate pcd

Vmc programming || pcd programming || how to calculate pcd vmc tool offset || vmc work offset || vmc machine offset || vmc machine settings

vmc tool offset || vmc work offset || vmc machine offset || vmc machine settings vmc machine programming || rpm calculation || feed calculation || cutting speed कैसे निकाली जाती है

vmc machine programming || rpm calculation || feed calculation || cutting speed कैसे निकाली जाती है Macro Variable for CNC

Macro Variable for CNC Helical milling on a CNC milling machine - CNC training course

Helical milling on a CNC milling machine - CNC training course Hole dialing for cordinate measuring (vmc)

Hole dialing for cordinate measuring (vmc) vmc programming || circular pocket in vmc machine

vmc programming || circular pocket in vmc machine vmc machine outside dialing || Dial Stand use in vmc machine || How to daling round part || offset

vmc machine outside dialing || Dial Stand use in vmc machine || How to daling round part || offset